Do you wonder how your smartphone and other gadgets’ plastic cases are made nowadays? If you think that using the traditional plastic mould technology is still being used today, you’re partly correct. However, for those companies who tend to make plastic cases in mass production, 3D printing technology is now widely used. To those who didn’t know, 3D Printing isn’t the kind of printing that your own regular household printer does. In order to say things straight, the word printing is just used because it uses a pattern that is being detected by the computer and made by means of a special 3D printing machine.

The truth is, there are many kinds of 3D printing, four of which are in commercial use today. Listed below are the types of 3D printing and their uses in technological advancement for today:

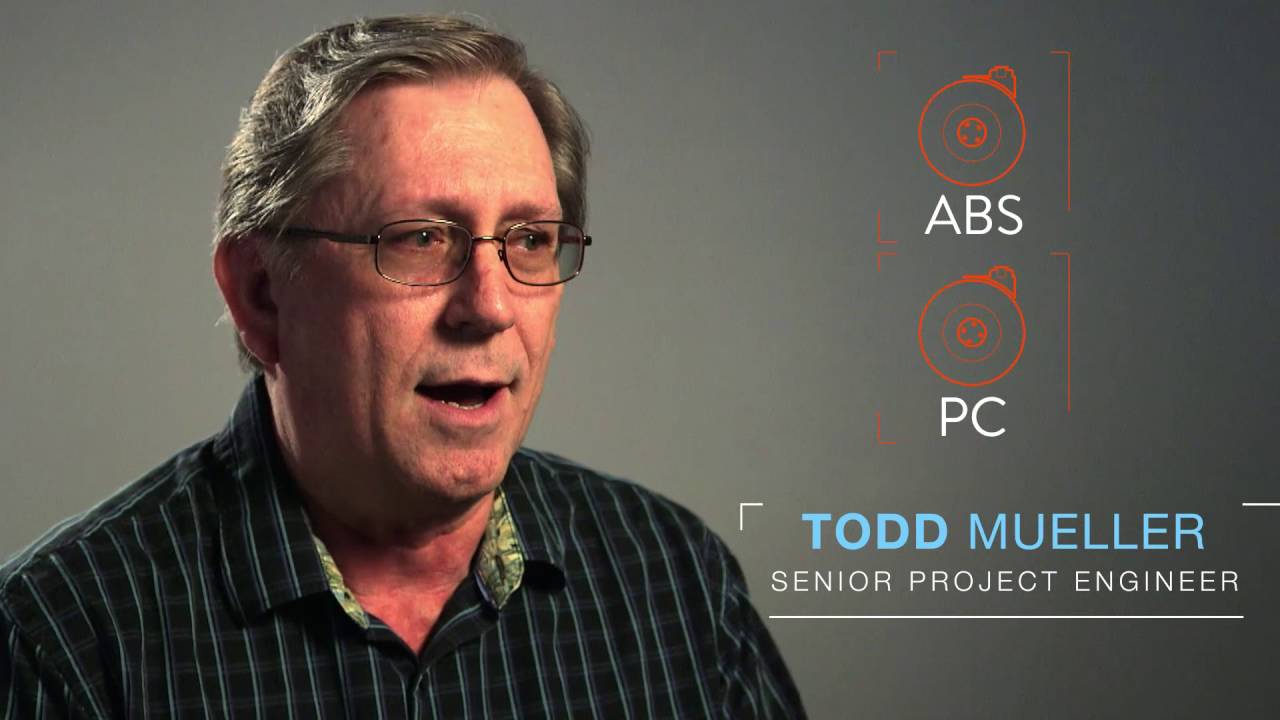

- Fused Deposition Modeling (FSD) – Even though this is somewhat advanced by miles when compared to regular printing, the printing concept is almost the same. Instead of using colored inks, the FSD Printers use polylactic acid (PLA) or another polymer product such as acrylonitrile butadiene styrene (ABS) plastics as raw materials for printing. The plastics are being melted inside the printing machine and then squeezed out in the nozzles that are located in the printing head. Depending on the model that is being made, the molten plastic is squeezed then being piled up in order to make the 3D version of the printed model.

- Selective Laser Sintering (SLS) – Unlike in FSD printing, the SLS uses polymer-metal powders or other materials such as nylon or aluminum in powdered form. By using a laser as a guide, the machine sprays the powder into the pattern before being melted and fused by the laser. The spray-laser fusing action occurs in less than a second in repetitive style until the 3D model that is being printed is finished.

- Polyjet Printing – Being one of the rising 3D printing methods nowadays, Polyjet Printing somewhat works like a combined version of FSD and SLS Printing. Instead of semi-solid, Polyjet Printing uses a liquid polymer in printing 3D objects, which is then being joined together by means of using ultraviolet rays. This kind of printing allows hybrid or multi-material printing. However, it is not capable of printing large-scale models.

- Stereo Lithography – If polyjet printing uses a liquid polymer, the stereo lithography printing uses a liquid resin as its printing material which provides a matrix for every printing layer. The specific parts are then hardened by an ultraviolet laser while leaving the rest of the resin as liquid. The entire process is repeated until the 3D product is finished.

https://www.youtube.com/watch?v=a_kbMUzMKk0